- #MICROSOFT DYNAMICS RMS PHYSICAL INVENTORY SERIAL NUMBER#

- #MICROSOFT DYNAMICS RMS PHYSICAL INVENTORY UPDATE#

What if I have multiple lot numbers to count for the same item? Expected on the physical inventory order when you are nearly completed. Just go ahead and add the item onto the recording. What if I have found an item that does not exist on the list? Expected function to get the latest calculated quantity. List to get a report view.įAQs What if purchase and sales transactions happen between when I create the order and start the count? The system will then calculate the positive and negative adjustment for each line.

#MICROSOFT DYNAMICS RMS PHYSICAL INVENTORY UPDATE#

If so, please select Action > Function > Calculate Expected Quantity to update the line. This means you may not have it on hand according to the system or you may not have ever transacted with it. box is not checked for a line, that indicates the line does not exist in the original plan.

#MICROSOFT DYNAMICS RMS PHYSICAL INVENTORY SERIAL NUMBER#

During the recording, if your organization uses lot number or serial number tracking, you can fill out the lot number on the line level.Assign Anette (AH) to process Recording 1 and John (JR) to process Recording 2. Then another user, John Richards, would count the remaining items. One recording is assigned to one warehouse user, Anette Hill, who would count only CHAIR Items. In this example, let’s say we’ll create 2 recordings out of the physical inventory order.

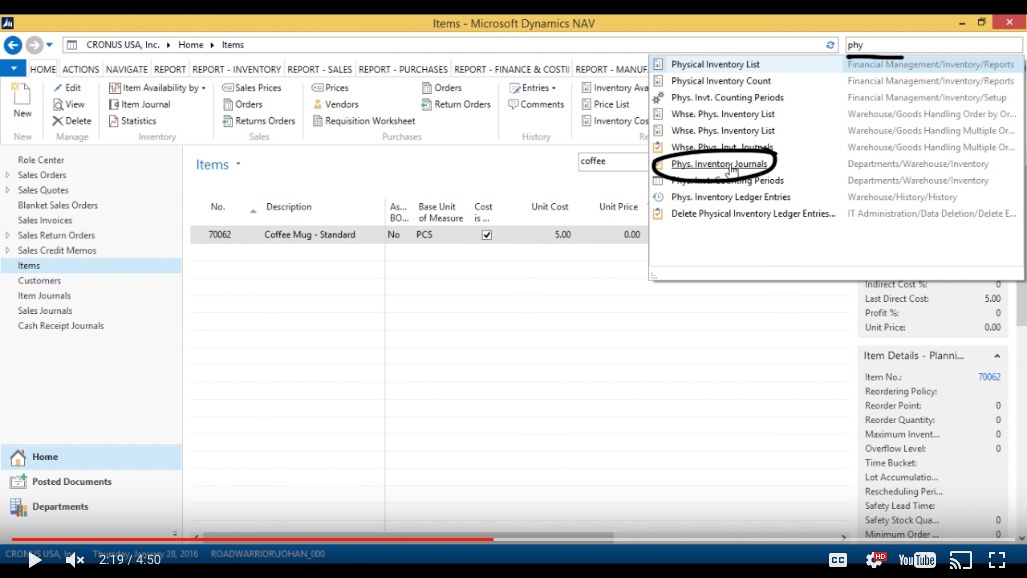

Use the “Calculate Lines” function to obtain the current system count.By filtering to the location only, the system will provide you with the expected inventory quantity for each item that you had transacted before.You can also assign yourself or another member of the team to be in charge of the count. Provide a description for your stock count and specify the location that you wish to count.Search for “Physical Inventory Orders” within Business Central.Determine how you would like to perform the count: Provides a solution to your warehouse count when directed pick and put-away is not enabled.Integrates very well with scanning devices.Simplifies distributing inventory count to several warehouse staff.Alleviates some of the challenges or need for custom modifications around inventory counting when you use lot number or serial number tracking.

0 kommentar(er)

0 kommentar(er)